BASF is the leading oxidation catalyst supplier to the power generation industry. We have been servicing the power generation industry for over 20 years with over 700 units operating or under construction. BASF customers value our experience and technical expertise as the premier supplier of oxidation catalyst solutions to the power generation industry.

Technology Description:

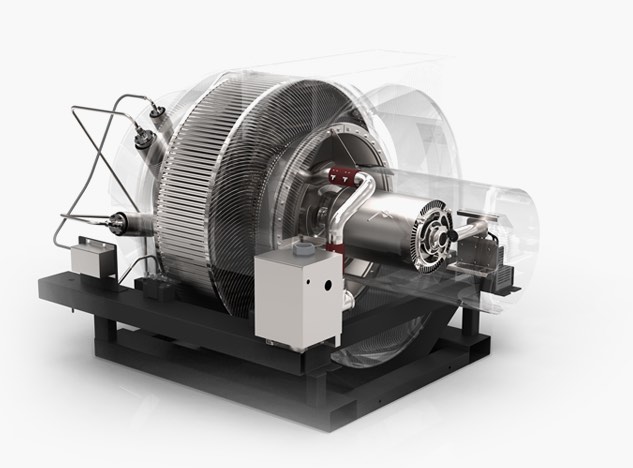

Thousands of our high performance, low maintenance environmental catalysts are in use around the world, helping industrial leaders in power generation, process industries and other applications, reduce pollutants. Our solutions include CO oxidation catalysts (CO catalysts) to remove carbon monoxide (CO), VOC catalysts (VOC oxidation catalysts) to remove Volatile Organic Compounds (VOC) including halogenated hydrocarbons, SCR catalysts (Selective Catalytic Reduction catalysts) to remove NOx (nitrogen oxides) and N2O (nitrous oxides), ammonia destruction catalysts to remove ammonia, catalysts to remove methane (CH4), catalysts for the food industry, and sorbents to remove mercury. As a pioneer in the clean air industry, we have a broad range of competencies to meet customer requirements for air quality and regulatory compliance. We are leveraging our expertise to help customers find solutions to improve air quality wherever needed.

Our breadth of experience encompasses virtually every make, model and turbine configuration. Our R&D, application and project engineering staff expertise ensure maximum performance for both new source applications and replacement catalyst for existing applications.

Nearly all of the power generation oxidation catalysts that we have supplied are still running. More than 300 units are six to ten years old and over 200 units are greater than ten years old. No one else in the industry approaches the durability or number of installations of BASF oxidation catalysts for the power generation industry.

BASF Catalysts has long been a leader in the development of highly active, robust and selective catalysts and related technologies for the destruction of volatile organic compounds (VOC). While there are a number of methods to abate VOC emissions, catalytic incineration has become a leading choice because it can be more versatile and economical than other approaches. Our VOCat™ VOC catalysts control emissions of hydrocarbons (HCs) and other VOC from a wide variety of industrial processes, including chemical processes, paint systems, food processing, printing, electronics, and soil and groundwater cleanup systems. They help customers meet increasingly stringent emissions standards reliably and cost-effectively.

Currently Seeking:

Direct Sales (Exports)

Ready to connect with BASF Corporation? Click here.

Visit the company’s website.